Technical Benefits of using waterproofing admixture for concrete and cement

Concrete and cement treated with our advanced admixtures becomes highly water-resistant. The mixing ratio is about 1:100, e. g. use only 1 kg of our waterproofing admixture to get 100 kg waterproof cement.

These additives, typically chloride-free aqueous solutions based on complex alkaline earth silicates, react chemically with Portland cement. This reaction densifies the cement matrix, significantly reducing water permeability and the penetration of chlorides found in deicing chemicals, seawater, and salt spray.

Such additives improve workability, strength, and waterproofing properties of hydrophobic concrete, with minimal impact on setting times. They are compatible with various other additives, including fly ash, microsilica, ground granulated blast-furnace slag, Type K cement, plasticizers, and air-entraining agents. Generally, a dosage of 0.9 liters per 100 kg of cement is recommended. These additives can be mixed into concrete at the plant or on-site.

Scientific Basis

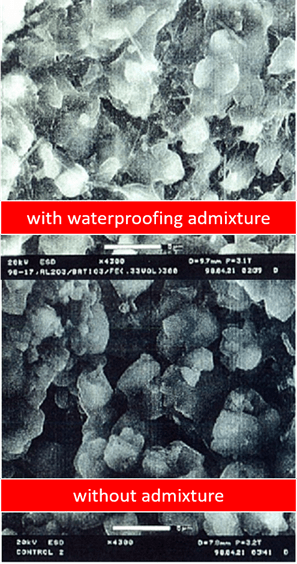

These chloride-free, inorganic complex copolymers based on alkaline earth silicates react with Portland cement, densifying the cement matrix. This significantly reduces concrete permeability and the ingress of chloride ions, thereby greatly lowering the risk of chloride-induced corrosion of steel reinforcements in concrete structures.

Effect of waterproofing admixture on concrete

Effect of waterproofing admixture on concrete

Practical Applications

Our advanced concrete admixture are used to enhance the durability of concrete in both above-ground and underground structures, which are often subjected to accelerated damage due to their location or use. By significantly increasing water impermeability, these additives provide enhanced protection against steel reinforcement corrosion.